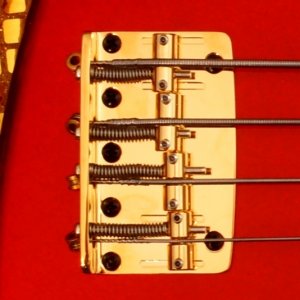

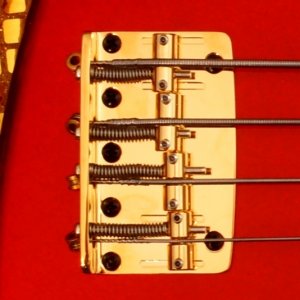

Bridge

Our standard configurator bridge is from GOTOH. Is there anything special about it? Absolutely! Three details you probably won't see at first glance, but they make all the difference.

First, that bridge may look like a simple bent-steel model but in fact it is made of 3 mm brass and it has brass saddles. It weighs 150 gr, same as a respectable high-mass bridge, whereas bent-steel models typically weigh in at 100 gr.

Second, the base plate has guideways for stabilizing the saddles sidewards. These guideways keep your strings from veering off and messing up your elaborate intonation.

Third, here's a question for you: Who has a bass at home that somehow never builds up enough oomph, always sounds a little weak for no obvious reason? Take a piece of paper and try to slide it under your bridge base plate. There you have your reason!

A surprisingly high number of bass bridges does not have full contact with the body. It's a design flaw. All mounting screws line up neatly at the back end, whereas the base plate sticks up at the front end. Disaster for the output.

So what does the shrewd bassist do about it? He drives the screws in even harder and wonders why that gap at the front end is getting ever larger.

Neither the base plate nor the body finish are perfectly even, a situation aggravated by the ground wire jammed in below the bridge. So if you bury your bridge deeper into the finish on one side, no wonder it has to rise up on the other side.

GOTOH has the right solution: mounting screws on all sides of the base plate.

TUNING MACHINES

- Compact design made of lightweight fine zinc alloy

- Die-cast precision gear, enclosure-protected and lifetime-lubricated

- Ease of rotation is individually adjustable by adjustment screw

- Gear ratio 1:17

- String retainer in tuner color

- 2 models at choice, Y shaped and clover shaped

Wiring

BITE electronics are exclusively built of passive components, this means your BITE bass has no on-board battery. We consciously bank on a passive design which experience has shown to be extremely resilient.

The painful embarrassment of an empty battery on stage has been known throughout the history of active basses, but a passive bass also copes way better with odd stage setups than an active one. The last thing we want is you on stage without any signal.

Weak output is certainly not an issue, your BITE bass outperforms most active models hands down with his 1000 mV pickups.

For those of you who are into modifications, here are the tech specs:

The Jawbone Wiring

The Jawbone is wired in traditional JB manner:

1. Opposite poles: The two pickups have opposing magnetic polarities (a question of north and south).

2. In phase: The pickups are connected in phase, this means the fluctuations of electric potential have the same polarities at the same time (a question of plus and minus). A popular and very easy JB modification is swapping to out-of-phase. Just swap the lead wires of one (not both) pickups at their clamp or solder connections. Whoever considers that old in-phase sound as too bassy, will now enjoy a twangy funk. Mind you, out-of-phase has less output and only works, if both pots are turned open.

3. Reverse wiring for independent volume control: The hot pickup wires connect to the middle lugs of the volume pots (that's where the sweeper is) instead of the usually designated left lugs. This prevents shorting the joint signal to ground when turning down only one volume pot.

4. Parallel

And what does all this do for you, you ask?

You can control both pickups independently. Jointly they work in noise cancelling humbucking mode. Not that it really matters though, because your BITE bass is noiseless by design anyway. It has a single-digit-ohm shield all around and is thoroughly grounded.

More important is the law of the parallel circuit. The combined resistance is not the sum of the single resistances (like in a series circuit) but the reciprocal value of the reciprocal sum. In practice this means for you that the neck pickup alone will give you more output than both pickups turned up. The lowest ouput will come from the bridge pickup alone, but the blame for that has to be taken by the pickup position at the end of the oscillating string.

The wiring principles of the Jawbone JJ apply also to the Jawbone PJ and RPJ, where the split coil is connected as one pickup, just like a single coil.

The Punch Wiring

As for the Punch electronics, there's not much to write home about. Both coils cannot be controlled independently, that wouldn't make much sense as each coil covers only two strings. For the record: opposite poles, in phase (plus connected to minus), in series and connected in an orderly manner to the designated pot terminals.

Snap Connectors

If you wish to be able to perform pickup modifications without soldering, we install solderless and fail-safe clamping technology which was originally developped for ship building. You heard us right, our snap connectors are certified for ship and railroad building. It is safe to assume that what is made for the cold, heat and humidity of the high seas, is well-prepared for the hardships of your rehearsal basement. Our snap connectors also match any good solder connection in terms of mechanical resistance against pull and vibration as well as electrical contact resistance.

Shield

Electromagnetic radiation interferes permanently from all sides. That cable clutter on stage, that neon tube in your rehearsal room, that notebook on your desk. They all cause nasty noise, but only if one lets them do so.

We won't. We apply a special coating which was developed for shielding airplanes and life support equipment. It is hundred times more conductive than conventional graphite or copper shield.