BITE Philosophy

Quality is not an accident. It's the result of high intentions, sincere effort and skillful execution.

Our Mission

We build quality custom basses for professional and amateur musicians.

Our instruments feature a strong and clear output signal and unique customization options.

We are mindful of our responsibility towards man and environment. We consciously do not use wood from tropical rainforests, nor do we make unverifiable marketing statements about the tonal properties of wood in musical instruments with electric sound generation.

Guitar Building 4.0

The concept of manufacturing 4.0 is aimed at speedy and affordable customization. This is exactly what we do for the bass guitar.

Here is a video showing our production and here are the cornerstones of our production:

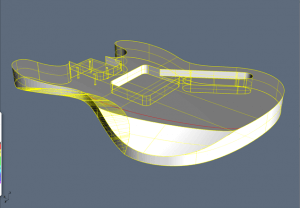

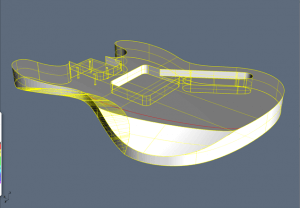

Digital Production

Computer-controlled manufacturing is not only time and cost efficient, but above all it makes each production step exactly repeatable. The result is an unrivalled advantage in quality.

Luthier's Workshop

Artisanal skills, the keen eye and trained hand remain indispensable in premium guitar manufacturing despite all digital CNC and laser technology. We level first the fretboard by hand, taking into consideration the growth specifics of each piece of wood, and then the frets, something laser plekking cannot deliver. Our fret ends are also rounded and polished by hand. Our luthiers are mostly graduates from the 4-year Bowed and Stringed Instruments School in Hallstatt (HTBLA), Austria, a demanding professional education, recognized among the best worldwide.

Neck-body coupling: as tight as it gets

Fretwork

3-ply wooden pickguard walnut-maple-walnut with amber pearl inlays

Custom sanding by hand

Division of Labour

Anyone who in medieval times commissioned a plucked instrument knew that the lute maker did it all by himself. He cut the tree, stirred the finish and twisted the gut strings.

Today, even the highest-priced custom segment is based on division of labor. Pickups, electronics, metal and plastic components, strings, PU lacquer, everything is supplied by specialized subcontractors who often have exclusive patents and a specialized workforce.

We at BITE Guitars have both, facilities to build basses from raw blocks of wood and specialized partners who manufacture individual components according to our technical specifications and quality requirements. This allows us to respond flexibly to customer requirements.

Made in Austria

We are an Austrian family business. Guitar building is a regulated profession in Austria, you can only exercise it with an adequate education and qualification.

Our instruments are Made in Austria. We pay attention to the local content, the lion's share of value added is generated by ourselves and our Austrian suppliers.

Our Partners

- D'Addario® - USA

- GOTOH® - Japan

- Graph Tech Guitar Labs® - Canada

- LaBella® - USA

- Schaller Electronic® - Germany

- WAGO® - Germany

They all share that persistent drive for precision, quality and sophisticated solutions which makes them global market leaders in their respective product fields and thus ideal partners for BITE® Guitars.

Our sound partner: RoadtripMusic Studio & Label recording - mixing - mastering - super nice!

For their contribution to our product development, we owe special thanks to (in alphabetical order):

- Doz. Dr. habil. Gerald Koch, Johann Heinrich von Thünen Federal Research Institute, Institute of Wood Research, Hamburg, Germany

- Willi Langer, Head of Bass Section, Department of Popular Music, University of Music and Performing Arts Vienna, Austria

- Helmuth Lemme, physicist, developer of pickups and pickup measuring devices, author of the international reference work on guitar electronics "Electric Guitar: Sound Secrets and Technology", Munich, Germany

- Erhard Mayerhanser, bass player, Munich, Germany

- Eric Meier, The Wood Database, USA

- Johannes Neunteufel, professional bass player, University of Music and Performing Arts Vienna, Austria

- Gregor Nowak, Master Luthier, Deputy Guild Master of the Vienna Guild of Artisan Crafts and Musical Instrument Making of the Vienna Chamber of Commerce, Austria

- Daniel Riegler, Industrial Designer, University of Applied Arts Vienna, Austria

- Gina Schwarz, University Lecturer, Bass Section, Department of Popular Music, University of Music and Performing Arts Vienna, Austria

- Prof. Dr. Manfred Zollner, Professor em. of electroacoustics at the Technical University Regensburg, author of the 1.300 page scientific reference work on the physics of the electric guitar, President of the GITEC Forum for Electric Guitar Technology

- Dr.-Ing. Tilmann Zwicker, Board Member of the GITEC Forum for Electric Guitar Technology

Who Is BITE Guitars?

Wolfgang used to run the foreign office of an investment bank. The doctors didn't think this was a good idea, they advised him to radically change his course. Bass guitar seemed just the right thing to him, looking sufficiently radical. So he quit his job, bought a red Precision and set up a band.

However, rather than working hard on his bass playing skills, like any respectable bassist would do, Wolfgang preferred to occupy himself with entirely different stuff. How can it be that you can buy a brandnew bass guitar for 200 $/€ that just blows you away, while others for 2000 just sound like kids' toys? It didn't make any sense.

The banker in him began researching markets and business models, whereas the craftman's descendant in him brought his grandpa's old carpentry back to life. That abundance of tools and wood processing machinery came in handy now.

Initial tinkering soon evolved into serious product development efforts and a good amount of time and training courses later he was granted the luthier's license by Austrian trade authorities. He later became lecturer at the Guitar Summit, Europe's biggest guitar congress, and member of the German GITEC Forum for Electric Guitar Technology.

Wolfgang was soon joined by fellow luthier Sebastian, who incidentally also had grown up in the scent of wood of his grandpa's carpentry, somewhere between bandsaw and planing machine.

Sebastian's passion for wood has always been on par with his passion for music. No wonder he graduated with honours from the 4-year Bowed and Stringed Instruments School in Hallstatt (HTBLA), Austria. There, he had also been part of the research team which, in 2015, managed to decipher the centuries-old construction secret of Stradivarius violins. In addition, Sebastian is also a trained jazz guitarist and guitar teacher.

Thomas Milacher is our in-house bass professional. He graduated in electric and upright bass from the concert class of the Music and Arts University of the City of Vienna (MUK) and he holds the bass teaching degree of the University of Music and Performing Arts Vienna (MdW).

Thomas was involved in the development of our BITE 1000mV pickups from early on. His weekends as a gigging artist are generally booked out for months, whereas during the week he keeps working with us in production, social media management and rigorous testing to ensure our basses are up to professional expectations.

A small but efficient team in production and office completes the crew.

Climate Protection & Social Responsibility

This is about giving back. We manufacture without the use of tropical wood and we care about carbon neutrality.

Your BITE bass and its materials travel quite a distance until they reach you. Wherever possible we ship carbon neutral with our shipping partners.

Otherwise we make sure to contribute to adequate CO2 compensation through the trustworthy offset projects of climateaustria.at. They finance admirable projects in Austria and in developing countries where they do not only offset CO2 emissions but also create social and economic benefits for the local population.

Figured is beautiful

Wood at times displays streaks that intermit the overall grain pattern. Such discolored flecks can for example be the result of insect bites or mineral deposits in the soil. Often they are not visible on the raw log but come to light later, upon planing and routing.

Some guitar manufacturers resort to chemical bleaching agents, we don't. As long as there is no structural deficit in the wood, we are happy to use wood with individual character. More and more, such variations are now considered a desirable decorative feature.

In this video, Bob Taylor of Taylor Guitars tells the gripping story of ebony with white flecks which previously was left to rot in the rainforest after felling, and now has become a requested item.

FAQS

When we hit the scene in 2019 with our 1bn-basses configurator, the flashy webdesign and striking headstock, we caused a bit of a stir in the rather traditionalist guitar world. This is an edited summary of comments Wolfgang addressed in online bass forums.

Q: I applaud them for quite a few reasons. The owner quit his job in finance and thought this would be more fun. Kudos for that. Many folks take up golf to fill time, he starts a bass guitar business. Gets my vote, wish I could do the same.

A: Thanks for bringing up my personal history. BITE Guitars came about for a simple reason: the passionate bass player in me just wasn't completely happy with what he found in stores in terms of choices, prices and sound.

Q: Is it top notch quality or lower quality stuff? That I have absolutely no idea of.

A: We are not in it for the quick buck, we do nothing on the cheap and we do not source in China. We try to be as transparent as possible, pls check out "Guitar Building 4.0" above. Our production is highly digitalized for consistent quality and still our head of production is a licensed luthier who also builds violins with the craftsmanship of his own hands (in Austria you need several years of training, a craftsman examination and a compulsory license to build guitars).

Our basses were developed in cooperation with professionals from the University of Music and Performing Arts Vienna and the venerable luthier school in Hallstatt. They were scrutinized and tested by the knowledgeable audience of the Guitar Summit's boutique area, notably trade journalists and bass professionals. Response was overwhelming and till this day we haven't had a single quality complaint. How many bass manufacturers employ graduate bass professionals to QC and test slap each instrument? We do anyway.

Q: The idea of colored pickup covers is unique, nobody had the intestinal fortitude to attempt something so brazen before.

A: Thanks, we do things differently, from the product design to our online configurator to the way we organize production. Whenever you do things differently, bend traditions, this will inevitably raise eyebrows and questions. I'd be surprised if it didn't.

Q: I like the concept of fast custom builds. But they should have consulted bass players instead of Hello Kitty for the graphic choices.

A: You made me laugh over here, thanks! 🙂 If you want to visualize over 1bn bass configurations, there is no way around graphics. The user has to see what he gets immediately upon his click, otherwise the configurator is pointless. And it'd better be in high resolution.

We have put in enormous amounts of time and resources to develop this CONFIGURATOR, the result being that you can build your bass through 16 choices in no time, actually under a minute. Anytime you want to see actual photographs of our models, you can do so in our MEDIA GALLERY, on Instagram and Facebook.

Q: Their web design looks a bit out of place.

A: The flashy colors are all my fault, I just want our website and configurator to be a refreshing experience. I fully acknowledge that our colorful webdesign is something unusual in the guitar world.

Q: High-output pickups are not an advantage at all, high output in the passive world usually means darker tone.

A: Usually yes, you are right. We, on the other hand, had Germany's foremost scientific pickup experts contributing to our proprietary pickup development, GITEC president Prof. Manfred Zollner, GITEC board member Tillmann Zwicker and renowned pickup physicist Helmuth Lemme. We finally achieved what we had in mind: passive pickups with a record output but still a clearly articulated growl that cuts through the mix even with tone rolled off, no muffled mud. Hear it for yourself in Nathan Navarro's review.

Q: They should find a way to make it like those online t-shirt places. You upload your graphic, and they get it on your instrument.

A: We can get your graphic on both, the pickguard and the body. For the pickguard, you can upload, rotate, scale and position your design directly in step 8. of our CONFIGURATOR. By contrast, personalized artwork on the body is an interactive thing. It will most likely require graphics work on our part which we can only price when we know what you have in mind. This is why we offer to apply your graphic on the body in our MORE OPTIONS menu instead of the configurator.

Q: Offer better body colours, seriously, enough with the bursts/blacks/whites, we want cool colours.

A: You can get all the cool colors you want as individual builds in our MORE OPTIONS menu.

What's the thing with MORE OPTIONS anyway? For technical reasons and for easy use we focus our configurator on the most popular choices. Again, we are talking about a billion different basses already. We can of course do a lot more than that. This ranges from special body finishes and individual artwork all the way to implementing special wiring ideas. Those are things that need a little interaction between you and us and require individual pricing.

Q: Can I hear the logic explained for a P pickup at the bridge, and J at the neck?

I’m assuming there’s a reasoning behind the design...

A: Thank you for asking. Our single and split coils vastly differ in their build properties: wires, turns, cross sections, magnetic shapes and field lines and other parameters. These differences result in different tonal properties, irrespective of the pickups' positions along the strings. This is not a mere question of twangy vs. bassy but of multi-layered sound colors. It is part of our firm's DNA as a newcomer to try out stuff off the beaten track, be it the visual appearance or the sound of our basses. As an example, check out our menu allowing users to choose from several hundred sound configurations, all purely passive. We find this interesting and fun and we are very thankful that the overwhelming majority of users share our idea of curiosity and fun.